OUR PRODUCTS

Disc Return Roller

The HMA Rubber Disc Return Roller is ideal for use on

short installations in wet, sticky or abrasive conditions

to help avoid unwanted build-up on the conveyor

return roller, or carry back on the conveyor belt itself.

The build up of material on the roller surface will cause

irregular wear of the shell. A change in shape of the

roller leads to conveyor belt mistracking, damage and

ultimately failure.

Quick info. -

- Standard JIS/CEMA/DIN/ISO

- Roller Dia. ⌀ 180~⌀195mm [⌀4.25"~⌀7.68"]6204~6308 2RS

- Seals Triple/quadruple labyrinth

- Disc Material Rubber/PU/FRAS rubber/Ceramic

- Size Be customized

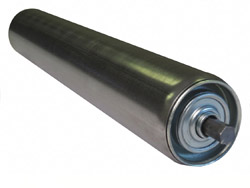

Direct Replacement Roller

We use heavy duty machined cast iron end covers on all our rollers.

These castings are precision bored and externally grooved to engineered tolerances.

Housed inside this cast iron end cover is our double rubber sealed and lubricated for

life 2RS C3 bearings which is situated behind a separate double lip rubber seal.

Having the bearing seated inside the casting protects it from external environment conditions,

ingress of moisture, dirt or destructive particles that causes bearing damage and breakdown.

Our design and construction gives ultimate bearing protection resulting in a superior roller

delivering long life and reliable performance, every time.

Quick info. -

- Our replacement rollers are manufactured in mild steel in 101.6mm,127mm,159mm & 168mm diameter, with shaft diameter of 22mm – 45mm as required.

Garland Idler Roller

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem

Ipsum has been the industry's standard dummy text ever since the 1500s.

Applications -

Quick info. -

| Belt Width | Face Length | A | B | Mass Idle Set |

|---|---|---|---|---|

| 600 | 220 | 885 | 150 | 15,0 |

| 750 | 270 | 1040 | 180 | 17,1 |

| 900 | 330 | 1195 | 215 | 19,8 |

| 1050 | 390 | 1345 | 250 | 22,5 |

| 1200 | 450 | 1500 | 285 | 25,5 |

| 1350 | 500 | 1650 | 310 | 28,0 |

Full / Half Gear Coupling

Gear Couple is manufactured using excellent quality raw material and latest technology by our skilled professionals.

In order to ensure quality, these couples are stringently tested on various parameters by our experts. Apart from this,

remarkable quality and durability increase the demand of our offered range in the market.

Features: -

- High strength

- Precise dimensions

- Rust resistance

Flexible Gear Coupling

Under the misalignment condition of two shafts of the equipment, the teeth contact in case of straight cut hub will be as minimum Read More

Function and Properties: Gear Couplings: -

- The high tooth contact and high-quality gearing create high torsional rigidity.

- Low restoring forces are imparted while compensating for shaft misalignment.

- The special geometry of the gearing also allows for large offset values during operation – whether they be lateral, angular or axial.

- Secure torque transmission is achieved by precision shoulder bolts with fine threads.

Conveyor Rollers

Roller conveyor systems, due to their adaptability and usage, are used widely in numerous

industries, predominately logistics and manufacturing. There are several industries roller

conveyors are used in including the examples listed below:

- Coal Mines

- Food handling

- Packaging

- Logistics

- Mail delivery services

- Baggage handling

- Steelmaking

- Manufacturing and design

Tapered Cross Drill Bits

Titan Tapered Cross drill bit is usually used on hard and abrasive rock.

Cross shape makes drilling fast on the conditon of middle twill working section.

They are widely used on quarry, construction drilling and mining.

Bit diameter: 32mm ~ 45mm.

Color: Metal color or customized.

Taper degree: 4°46', 6°, 7°, 11°, 12°, or customized.

Shank Size: Hex.22mm

Other size can be customized.

They are widely used on quarry, construction drilling and mining.

Bit diameter: 32mm ~ 45mm.

Color: Metal color or customized.

Taper degree: 4°46', 6°, 7°, 11°, 12°, or customized.

Shank Size: Hex.22mm

Other size can be customized.

Regular Model as following:

| Size mm | Button Size mm | Taper Angle×I.D. | Item No. |

|---|---|---|---|

| 32 | 6.5×10.5 | 7°×22mm | WTES32-722 |

| 34 | 6.5×10.5 | 7°×22mm | WTES34-722 |

| 36 | 7×11 | 7°×22mm | WTES36-722 |

| 38 | 7×11 | 7°×22mm | WTES38-722 |

| 40 | 8x12 | 7°×22mm | WTES40-722 |

| 42 | 8x14 | 7°×22mm | WTES42-722 |

| 45 | 8x14 | 7°×22mm | WTES45-722 |

Threaded Button Bits

Threaded drill bits include general,retrac and reaming three series,with stronger button-fixing ability,longer service life,

better wear-resistance and impact-resistance performance,widely used in tunneling,underground mining,open pit mining,anchoring and

other large-scale construction projects.

Advantage of our thread rock button bit: -

- Threaded drill bits are equiped with the hydraulic drilling jumbo and used for crush rock, which are widely used in the tunnel construction, large scale mine open and underground) and large section tunnel advance in metal mine.

- We can make all kinds of threaded drill bits, that include R25, R28, R32, R35, R38, T38, T45, T51,ST58, GT60, ST68 and so on, and the head diameter range from 41mm to 127mm.

- Our R&D team will develop the sharpest industry "teeth", the most suitable bits for different application. The bits with sharp buttons are suit for harrd and mid-hard rock, and have excellent wear resistence and driving speed. The bits with round buttons are extensively used in hard rock with high abrasion and impact resistance.

- Our button bit is made of top quality steel and tungsten carbide same with well-known brand in the world. For the technic, we take “hot-insertion” processing procedure to insert the buttons into the bit. Optimized designs improve the drilling efficiency. And automatic production line ensure the quality stability of product. Strict requirements of heat-treatment guarantee durability of the bits.

Product specification:

| Bit body type | EX: Regular skirt, Retract bit, Guide bit and Beaming bit |

|---|---|

| Bit head type | EX: Drop Center (DC), Flat Face(FF), Convex, Concave |

| Thread type | EX: R25, R28, R32, R38, R3212, T38, ST58, etc |

| Carbide Button type | EX: spherical, ballistic, parabolic etc |

Button Mining Drill Bits

suitable for powerful percussive drills and top hammers with high speed drifter,,such as Atlas Copco 282 rocket

boomer,Atlas Copco 352 rocket boomer jumbo,AtlasCopcoD7roc,FurukawaHCR 1200, Tamrock,and Ingesoll Rand ECM660,

he products are widely used in bench and production drilling, extensional drilling,our products with comparative

advantages of the more prominent cost-effective as the famous brand in the world, our products have been recognized

as high-quality brand of rock-drilling tools made in India.

Premium designs and steel and premium tungsten carbide insert grade T6 supplied by Boart Long year, Offers industry-leading strength and penetration rates for more productivity Excellent straightness and hole clean quality ,Get max.drilling performance for rock drill.

Premium designs and steel and premium tungsten carbide insert grade T6 supplied by Boart Long year, Offers industry-leading strength and penetration rates for more productivity Excellent straightness and hole clean quality ,Get max.drilling performance for rock drill.

Advantages:

- i. Our products can match over 95% against the original products.

- ii. Price are competitive against the famous brands and best quality against the small factory.

| Product Name: | Thread Button bits |

|---|---|

| Description: | Thread Button bits Button bit Made with high quality of best quality alloy steel bar and tungsten carbide, through heat treatment like Atlas. |

| Material: | Alloy steel bar and tungsten carbide bit |

| MOQ: | No MOQ required for testing and trial order |

| Body Type | Normal type and retract type |

| Thread type | R22,R25,R28,R32,R38,T38,T45,T51,ST58,ST68,GT60 |

| Diameter | 32mm-152mm |

| Button bit shape | Spherical and Ballistic |

| Face shape | Flat shape and Drop-center shape |

Rock Drill Bits

115mm T45 T51 Mining Thread Rock Button Drill Bit , Find Complete Details about 115mm T45 T51 Mining

Thread Rock Button Drill Bit,115mm T45 T51 Mining Thread

Rock Button Drill Bit from Mining Machinery Parts Supplier or Manufacturer-R. K. Casting & Engineering Works Pvt.Ltd.

Sand Castings

With India’s sand casting industry consisting of more than 500 manufacturers spread

out from Coimbatore to Jharkhand the process of selecting a sand casting vendor can be

overwhelming. Here at R. K. Casting & Engineering Works, we simplify the buying process and reduce

the risk of working with foreign sand casting manufacturers. With headquarters in the Dhanbad

and sand casting manufacturing facilities in all over India, our buyers receive guaranteed delivery.

Manufacturing’s global supply other country, the end result is significant cost savings and reduced risk during your sand casting

process from start to finish.

Die casting

We are way forward in manufacturing and exporting Aluminium& Zinc Die Casting Components across the world.

As we ensure faultless quality products, we are entitled to receive considerable appreciation from our customers

spread all over the world. This type of die casting is made from tested quality raw material alloys. These castings

are tested for dimensions and chemical compositions and mechanical properties to meet our customers high standards.

We are using 3D Solidworks 2020 amd Auto CAD 2021 V24.0 Licensed software& Seimens UGNX12, for tool design. Z cadd for 2 D Design.

Applications -

- High Volume 2 WHEELER AUTOMOTIVE & LED Street Light Castings

- Range of castings to cater to Automotive Sector, Industrial Enclosures, Electrical Motors, Modular Furniture Sector, Lighting Sector,General Engineering.

- Over 27 types of castings in production

- 3 Die casting machines.

Low Pressure Castings

The low pressure die casting is a recently started casting process. Again the aluminium liquid is filled in the moulds and

allowed to cool and solidify. Since the cooling happens under a certain level of pressure the density of product created is higher.

On the other hand, the effect of casting generated is much better than if it is done by other processes.

Therefore this technique can be utilised to create the toughest of products and the most complex of castings as well.

Gravity Die Castings

Some of the products made using Gravity Die casting process are Housings, Junction boxes,

impellers, Valve bodies, Flanges, Manifolds, Actuator bodies, Compressor parts, Electrical fittings parts, Covers.

Permanent mould casting get their name from the fact that the process utilizes permanent metal moulds instead of temporary sand moulds for the casting process. Cast iron is the most commonly used mould materials as it offers great reliability during casting. The cores are made from other metals or sand. The cavity surfaces of the moulds are coated with fine layers of materials that have good heat-resistant properties such as clay or sodium silicate.

The moulds used in casting are pre-heated upto 200 ºC (392 ºF) before the molten metal is poured into the cast cavity. Casting has to be done with care in order to ensure that proper thermal balance in maintained throughout the casting process. This is done through a variety of ways including external cooling techniques using water or relevant radiation techniques.

Permanent mould casting, while not offering the same level of design flexibility and ease pattern usage as Aluminium Sand Castings, it has the advantage of offering relatively lower design and development costs as well as production costs. At VJP, we have the expertise to undertake permanent mould castings of complex components of diverse application in various industries.

Permanent mould casting get their name from the fact that the process utilizes permanent metal moulds instead of temporary sand moulds for the casting process. Cast iron is the most commonly used mould materials as it offers great reliability during casting. The cores are made from other metals or sand. The cavity surfaces of the moulds are coated with fine layers of materials that have good heat-resistant properties such as clay or sodium silicate.

The moulds used in casting are pre-heated upto 200 ºC (392 ºF) before the molten metal is poured into the cast cavity. Casting has to be done with care in order to ensure that proper thermal balance in maintained throughout the casting process. This is done through a variety of ways including external cooling techniques using water or relevant radiation techniques.

Permanent mould casting, while not offering the same level of design flexibility and ease pattern usage as Aluminium Sand Castings, it has the advantage of offering relatively lower design and development costs as well as production costs. At VJP, we have the expertise to undertake permanent mould castings of complex components of diverse application in various industries.

Gravity Die/Permanent Casting Capability -

| Max Weight - 100 Kgs | Economical Order Quantity - >1000 Number per annum | Surface Finish - 4 - 12 Microns |

|---|---|---|

| Max Size - 1500 X 800 mm | Casting Tolerance - ± 0.5 mm | Minimum Core hole size - 6 mm |

| Minimum Wall Thickness - 3.5 mm |

All Types Of Machining Works

As per client demand we do all types of machining works with latest technology.